Font size:

Print

Hydrogen Plasma Method Offers Carbon-Free Nickel Extraction

How extracting and producing nickel can be made more sustainable

Context: A new study published in Nature on April 30 by researchers at the Max Planck Institute for Sustainable Materials in Düsseldorf, Germany, introduces a groundbreaking method for extracting nickel using hydrogen plasma instead of carbon.

More on News

- Traditional nickel extraction methods contribute heavily to carbon emissions, with one tonne of nickel production generating over 20 tonnes of CO₂. This innovative approach significantly reduces carbon dioxide emissions while improving efficiency.

- Global demand for nickel is expected to exceed six million tonnes per year by 2040.

The New Extraction Methodology: Hydrogen Plasma

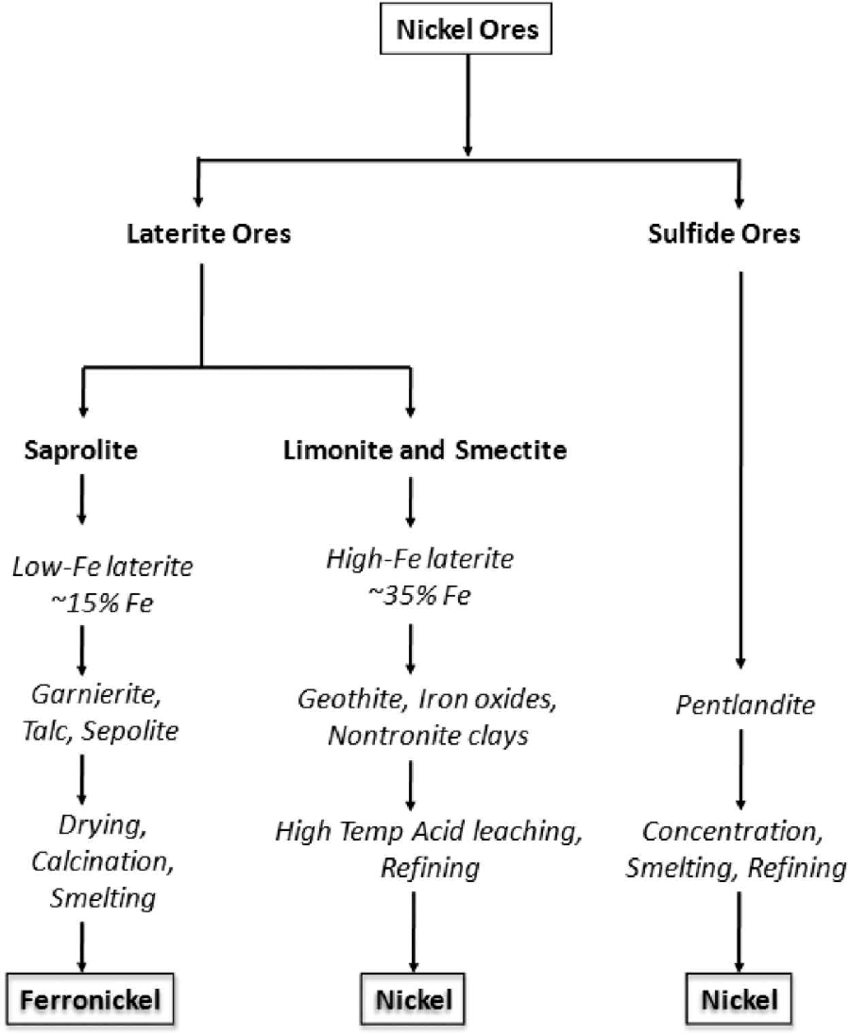

- Researchers bypassed the traditional multistep process (calcination, smelting, reduction, refining) and developed a single metallurgical step conducted in one furnace.

- The new method is up to 18% more energy efficient and cuts direct CO₂ emissions by up to 84% compared to conventional practices.

- Instead of using carbon, the process employs hydrogen plasma as the reducing agent and electricity as the energy source via an electric arc furnace.

- Hydrogen gas, when subjected to high-energy electrons in an electric arc, splits into high-energy ions, forming plasma—the fourth state of matter.

- This plasma rapidly reduces metal oxides, making the process cleaner and significantly faster.

- The reaction produces water instead of carbon dioxide, making it a carbon-free process.

- The technology supports India’s dual goals of accelerating industrialisation and infrastructure development while also advancing the country’s commitment to achieving net-zero emissions by 2070.

What is the importance of nickel?

- Nickel is a critical material in lithium-ion batteries, particularly in: Electric vehicles (EVs) – Enhances battery efficiency and lifespan. Renewable energy storage – Supports sustainable energy solutions.

India has nickel reserves primarily in the following regions:

- Odisha – Sukinda Region: Major nickel laterite reserves are located in Sukinda Valley, Jajpur district, Odisha. Found as nickeliferous limonite in chromite mine overburden with 0.4–0.9% nickel content.

- Odisha holds 93% of India’s nickel resources, estimated at 175 million tonnes.

- Jharkhand: Nickel is found associated with uranium deposits at Jaduguda. Singhbhum East district has 9 million tonnes of nickel resources.

- Chhattisgarh & Nagaland: Smaller deposits were reported in parts of Chhattisgarh and Nagaland. Nagaland has 5 million tonnes of nickel resources.

- Nickel is a key component in stainless steel, which is used in: Construction (bridges, buildings), Kitchenware (utensils, appliances), and Medical equipment (surgical tools).

- Nickel-based alloys are used in: Jet engines (high-temperature resistance), Military equipment (armour plating), and Spacecraft components (durability in extreme conditions).

- It supports the green economy by enabling sustainable material production. Many countries use nickel alloys in coins due to their durability and resistance to wear.

Major Indian Government Steps in Nickel Extraction

- National Critical Mineral Mission (NCMM): Its objectives include enhancing domestic exploration, mining, processing, and recycling of critical minerals such as nickel, lithium, and cobalt.

- Policy Reforms & Incentives: The government has amended the Mines and Minerals (Development and Regulation) Act, 1957, introducing an “Exploration Licence” for 29 deep-seated and critical minerals, including nickel.

- Block Auctions and Private Participation: The Geological Survey of India (GSI) has handed over 20 mineral blocks for auction as exploration licenses, with 12 blocks already notified for auction across states like Rajasthan, Karnataka, Maharashtra, Andhra Pradesh, Madhya Pradesh, and Chhattisgarh.

- Focus on R&D, Recycling, and Sustainability: The NCMM emphasises research and development, including pilot projects for new extraction technologies (such as hydrogen plasma methods for low-grade laterite ores) and integration of renewable energy in mining processes.

- Global Partnerships and Overseas Acquisitions: India is actively securing overseas mineral assets through initiatives like the Mineral Security Partnership and Khanij Bidesh India Ltd (KABIL).